Advanced additive manufacturing

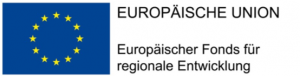

Makea develops hardware and software for extrusion–based additive manufacturing processes.

Our 7-axis industrial robot processes engineering-grade materials with short or endless fiber reinforcement. Developing our own slicer and printheads means there are little restrictions concerning size, layout and printing materials.

It also provides us with full control of layer height, orientation and printing materials while being able to print on pre-fabricated objects.

Having developed solutions for medical and automotive applications we are looking forward to your additive challenge!

Variable layer height & Constant layer width

Sample Part

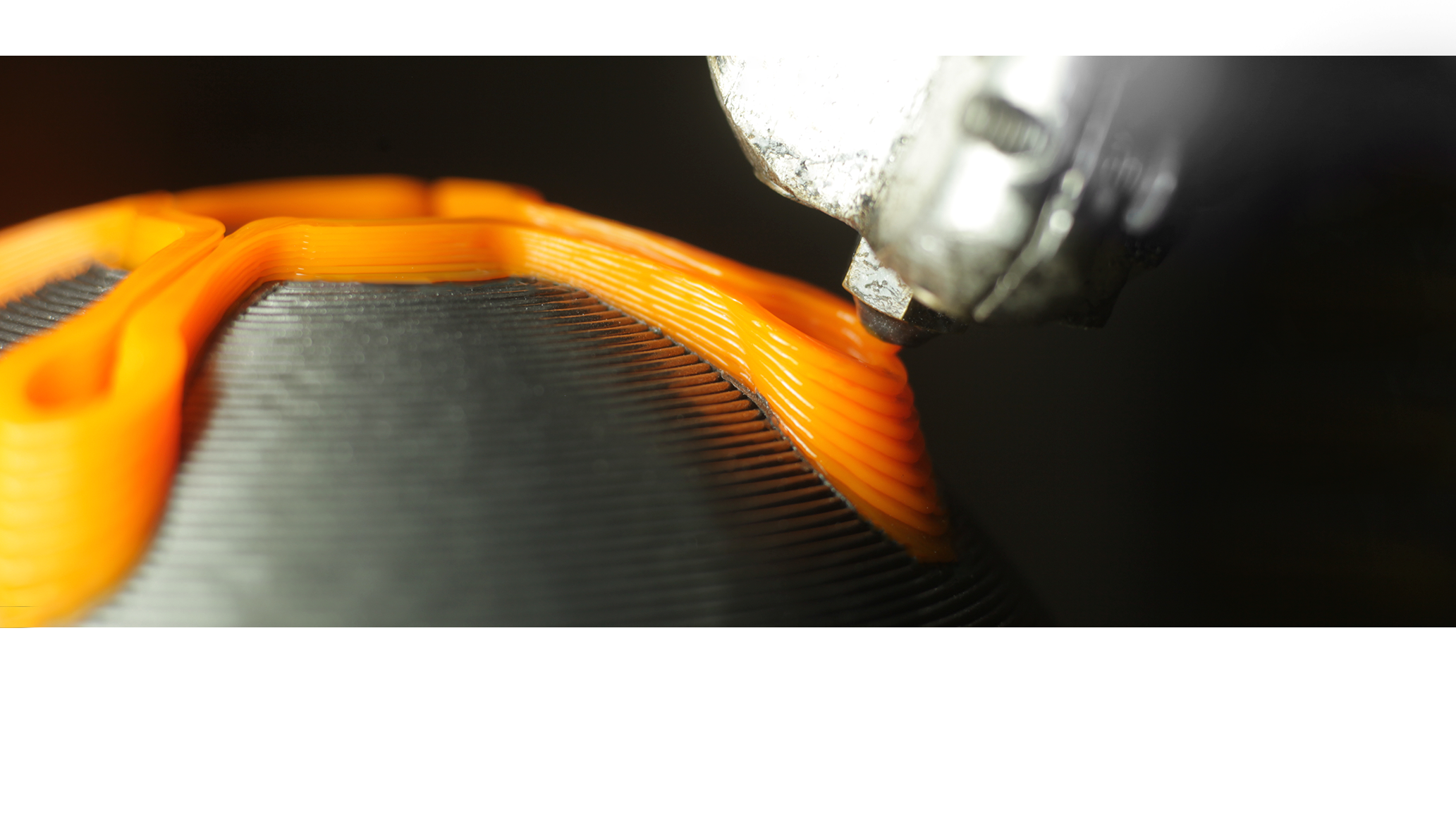

Continuous carbon fiber reinforcement

Application

Printing on pre-fabricated surfaces

Example